Same types for loose tongue?

From Christopher:

I wonder if there is an advantage to using the same type of wood when doing joinery work with loose nails. For example, if the work pieces are pine, would it be better to use the store-made pine dominoes rather than the white oak version from Festool? One wouldn’t use a completely different or oiled wood to make glued nails; but as for the usual suspects available in the building materials department, is this worth considering for the quality/longevity of the glued joint? I’d love to hear your thoughts.

Hard rock loosening tools with L tongue

For Duncan Gowdy, the L-shaped miter connection allows for a clearer assembly than traditional grooved miter connections

Domino System Is Changing The Game In The Furniture Industry

Tim Seleski offers tips and techniques for his revolutionary domino woodworking system.

How to make a floating tongue

Mill the tenon stock once the holes are sized.

Gorgeous or smooth nails?

From Luca:

Store-bought nails have these grooves to prevent glue from getting trapped in the bottom of the hole – but to me, the grooves look too deep. It makes me think that homemade nails without grooves would create a stronger connection. What are your thoughts on this issue?

Making hardwood screws

Choose the right wood and diameter for you to produce custom wood screws to fix small joints.

All about nails and cookies

Mario Rodriquez explains why nails and biscuits are suitable alternatives to traditional woodworking techniques.

Tool Review: DFM Pin Board

Mike Pekovich takes a look at a great wooden board that is being sold for a great price.

To CAD or not to CAD?

Also from Luca:

I just create designs and plans with pen and paper. I draw the project to scale, but I’m never confident that it will look good in real life from different angles. For my next bigger project, I’ll definitely make a full-scale model. But then I wondered if it was worth the effort to learn how to design a project using some kind of CAD software. In your experience, does that replace the need to design models to get the proportions right? Or have you ever designed something that you were very confident in and then once you finished building it, it didn’t look right?

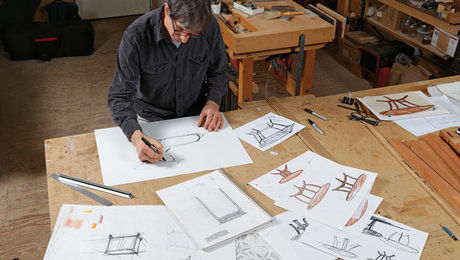

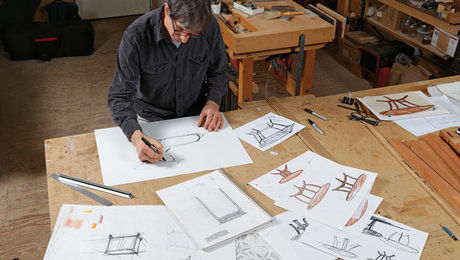

Authoring: A flexible design process

Keep options open from the initial idea to the final piece.

Every two weeks, a team of Fine Woodworking staff answers reader questions on Shop Talk Live, Fine Woodworking’s biweekly podcast. Send your woodworking questions to [email protected] For consideration in regular broadcast! Our continued existence depends on listener support. So, if you enjoyed the show, be sure to leave us a five-star rating and maybe a nice review on our site iTunes page.

Sign up for our e-newsletter today and get the latest techniques and how-tos from Fine Woodworking, plus special offers.